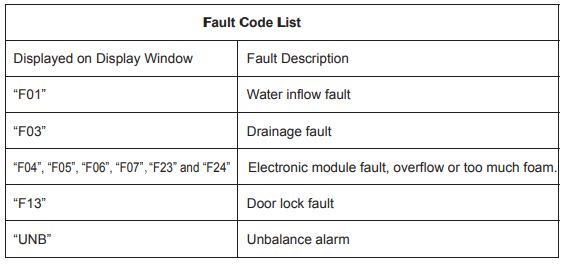

Hisense Washing Machine Error Codes

| Error Codes | Problem |

|---|---|

| F01 | Water inflow fault |

| F03 | Drainage fault. Not fully drained within 6 minutes. |

| F04 | Heating Error. The heater is out of order. Give an alarm after the washing course ends. |

| F05 | Electronic module fault, overflow or too much foam. |

| F06 | No Motor Speed Feefback Error. The rotation speed is not set as 0, but no rotation speed is detected within 3s or the rotation speed is below 20rpm, 5 attempts. |

| F07 | Motor SCR Short Circuit Error. 1. The rotation speed is not set as 0, but the measured rotation speed>set rotation speed+80, and last for 3 seconds 2. The rotation speed is set as 0, but the rotation speed rises rather than declines, exceeding 10 turns within 3 seconds. |

| F08 | Heater Circuit Error. The main control detected a heater circuit failure. This failure modes are checked before the cycle starts and after the spinning steps. |

| F12 | Heater Circuit Error. The main control detected a heater circuit failure. This failure modes are checked before the cycle starts and after the spinning steps. |

| F13 | Door lock fault. Start program for 20 sec and unlock the washer door(PTC) to check whether the door is closed. |

| F14 | EEPROM Error. The central control unit (CCU) receives its's data from an EEPROM onboard the CCU, if there is an error reading this data it will cause this error. |

| F15 | F17 indicates no water coming into the condensing chamber during drying. Unplug the appliance. Take the top off. Check to see if the condensing chamber below the heating chamber is blocked. |

| F21 | User Interface Error. -Check wiring connection to the display module. -Check display module. -Check control unit (CCU). |

| F23 | FWL Sensor Error. 1. The FWL sensor is out of order 2. When water level frequency maintain condition of below 10 kHz and over 30 kHz. |

| F24 | Water Level Reaches Overflow Level. Water is overflowing.(water level frequency is over 36.8kHz). If F24 is displayed, the drain pump will operate to drain the water automatically. |

| F26 | Pump Driver Failure. If the CCU detects during the wash cycle that the triac of the pump is defective it will display this failure. Check the resistance of the pressoswitch. A failure of the pressosswitch colud also cause the code. If OK start start service test to check CCU. İf the ailure occurs replace the CCU. |

| F27 | Reversing relay failure. If the CCU detects that the motor is possible to rotate only in one direction this failure is displayed. - Check the harness the motor. - Check the CCU. |

| F28 | Tapped Field Failure. If the CCU is not able to switch ON the tapped field of the motor this failure code is displayed. -Check if the correct motor is build in. -Check the resistance of the fields of the motor. -Check the harness between motor and CCU. -If the points above are OK replace the CCU. |

| UNB | Unbalance alarm. Press “Power Supply” key for 3 sec to turn off the machine. |

| FH | Water supply fault. Water tap closed. |

| FP | Draining fault. Clean pump. |

| FA | Water Stop fault |

| Fod | Over foaming fault |

Ensure that the water has cooled before draining the appliance. In addition, place a large container in front of the filter to collect water flowing from the filter.

- The drain hose is frozen up.

- Plug in the appliance again.

Select and start the ” Drain ” programme and restart the desired programme. If the fault occurs again, please contact After-Sales Service.

How to Fix Error Codes?

The appliance stops during the programme. For models with a remaining time display, a failure code between “F01” to “F07” and “F13″or “UNB”appears on the display.

If a failure code “F01″and “F02” appears on the display:

press the “start/pause” button to cancel the failure code and start the programme;if the fault persists,unplug the appliance and contact After-Sales Service.

If a failure code “F03” appears on the display:

Switch the appliance off and Check whether drain pump is blocked or drain hose is tied; if the fault persists, unplug the appliance and contact After-Sales Service.

If a failure code between”F04″ to “F07” appears on the display:

Switch the appliance off and select the desired programme; if the fault persists, unplug the appliance and contact After-Sales Service.

If a failure code “F13” appears on the display:

Check whether the door is closed or not and press the start/pausebutton; ” ” if the fault persists, unplug the appliance and contact After-Sales Service.

If a failure code “UNB” appears on the display:

Switch the appliance off and rearrange the clothes, then select the spin programme and start; if the fault persists, unplug the appliance and contact.

Before contacting After-Sales Service:

- Try to remedy troubleshoot the problem yourself (see ” Troubleshooting Guide”).

- Restart the programme to check whether the problem has solved itself.

- If the washing machine continues to function incorrectly, call After-Sales Service.

The washer stops when the program is running. The display window shows fault code “F24”, fault codes from “F04’ to “F07”, “F13”, “F23” or “UNB”.

“F01” displayed on screen:

The machine is not fed with water or insufficient water. Check:

- Faucet is fully open and has enough water pressure.

- Water inlet pipe is knotted or not.

- Filtering net of water inlet pipe is blocked or not (refer to maintenance and repair).

- Water pipe is frozen or not.

Press “Start/Pause” key after fault is removed.

If fault occurs again, please contact with after-sale service (refer to after-sale service.).

“F03” displayed on screen

The washer is not emptied. The washer stops the program being executed. Shut down the machine and disconnect power supply. Check:

- Drain pipe is knotted or not.

- Filter in drain pump is blocked or not (refer to the cleaning of filter in drain pump)

If fault code “F24” is shown

Water level reaches overflow level. Remove it by pressing “Start/Pause” key and feed water. Select and start required program. If fault occurs again, disconnect power supply and contact with after-sale service.

If fault code “F04” to “F07”, “F23” shown

Electronic module fails.

Press “Power Supply” key for 3 sec to turn off the machine.

After fault is removed, press “Start/Pause” key. If fault occurs again, disconnect power supply and contact with after-sale service.

If fault code “F13” is shown

Door lock is abnormal. Start program for 20 sec and unlock the washer door (PTC) to check whether the door is closed. Open or close it again. After fault is removed, press “Start/Pause” key. If fault occurs again, disconnect power supply and contact with after-sale service.

If fault code “UNB” is shown

Unbalance alarm.

Press “Power Supply” key for 3 sec to turn off the machine. Open the door and re-tidy clothes and then rotate program knob to single dehydration mode. Spin clothes to dry again. If fault occurs again, disconnect power supply and contact with after-sale service.

Error: FH

Red indication light is on: Water tap closed

Fault description: Water supply faul

Error: FP

Red indication light is on: Clean pump

Fault description: Draining fault

Error: F02 to F35

Fault description: Electrical module

Error: FA

Fault description: Water Stop fault

Error: Fod

Fault description: Over foaming fault

Hisense Washing Machine Troubleshooting

Your washing machine is equipped with various automatic safety functions. This enables faults to be detected in good time and the safety system can then react appropriately. These faults are frequently so minor that they can be resolved within a few minutes.

| Trouble | Cause |

|---|---|

| The washing machine will not start and no indicator lamps are on. | Check whether: The mains plug is inserted into the socket and the power switched "ON". The wall socket is functioning correctly(use a table lamp or similar appliance to test it). |

| The washing machine will not start. | Check whether: The door is properly closed (child safety). The "Start /Pause" button has been pressed. The Water tap is opened and press the"Start/Pause" button. |

| The appliance stops during the programme. | Check whether: The "Rinse Hold " indicator lamp lights up; terminate this option by pressing the "Start/Pause" button or by choosing and starting the "Drain" programme. Another programme has been selected and the "Start/Pause" button not be pressed.Reselect the desired programme and press the "Start/Pause" button. |

| Residue from detergent and additives left in the detergent drawer at end of wash. | Check whether: -The cover grid of the softener chamber and the separator of the main wash chamber are correctly installed in the detergent dispenser and all parts are clean. -Sufficient water is entering. The mesh filters of the water supply could be blocked. -The position of the separator in the main wash chamber is adapted to the use of powder or liquid detergent. |

| Machine vibrates during spin cycle. | Check whether: -The washing machine is level and standing firmly on all four feet. -The transport bolts have been removed. Before using the machine, it is imperative that the transport bolts are removed. |

| Final spin results are poor. | -If the laundry is still too wet at the end of the cycle, remove some articles of laundry and repeat the spin cycle. -Excessive foam formation may prevent spinning. Use the correct amount of detergent. -Check that the spin speed selector has not been set to " 0". |